Plastic yellowing leads to fewer markets, the upgraded product in Ruiqite to solve

Plastic products play an irreplaceable role in people's lives, ranging from daily necessities to plastic building materials. These products all have plastic shadows. However, many consumers have responded that these plastic products will yellow in the later stages, resulting in a bad appearance. Many plastics manufacturers are very upset about this problem, and expect the emergence of an additive to solve this problem.

As a company specializing in research and development, production of brighteners, yellowing agents and other chemical additives, the Ruiqite people decided to develop a new special brightener to solve this problem after inspecting the market, helping more dealers serve more end users.

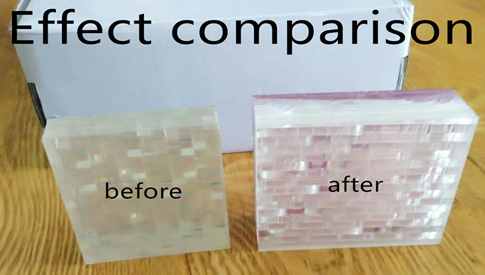

Under the leadership of Ruiqite Chairman Chen , Ruiqite's expert team and experimental staff after several weeks of testing, deployment, commissioning, and finally developed a plastic special yellowing agent RQT-TS-1. This yellowing agent can be used in the production or reprocessing of plastic products with the raw materials are evenly mixed in proportion to eliminate yellow light and achieve the purpose of bright colors.

Here are some profiles of this product:

A, product name: plastic special yellowing agent RQT-TS-1

B, product indicators: model NO. RQT-TS-1 Appearance: dark purple powder

Purity: ≥ 99% Operating temperature: 220 ° C

C, product introduction:

RQT-TS-1, a special yellowing agent for Ruiqite Plastics, is specially designed to eliminate the yellow light generated during the processing of plastic products and achieve the purpose of bright colors. (This product is used for all kinds of PVC plastic products to eliminate yellowing and decolorizing, the best effect), to yellow, anti-yellow and has a comfortable blue light, which can replace the yellowing effect of ultramarine.

D, recommended usage:

It is recommended to add 0.005-0.01% (50-100g in 1 ton of plastic products) to eliminate the yellow color in the product. Ingredients have recycled plastics to increase the amount added

E, Usage: When the product is mixed before hot melt, it can be evenly stirred for about 10 minutes. If the powder is dusty, it can be used together with some industrial white oil and plasticizer.

F, application scenario:

Can be used for PE, PP, PVC, ABS and other general plastic materials, can be used for blown film, blow molding, extrusion, injection molding, re-granulation and other plastic processing process to yellow, anti-yellowing (pvc material effect is best).

G, special remind:

Adding RQT series of fluorescent whitening agent products to white and colored products will have a "additive effect", and the product will be whiter, brighter and more beautiful.

The yellowing effect is only for the yellow light that appears during the heating process of plastic products. The optical principle "three primary colors" complement each other to eliminate yellow light, and the finished plastic products cannot be used.

H, packaging and storage:

2KG plastic PET barrels, packaging carton/24KG, 25kg cardboard drum. The sealed place in the dry place is effective for a long time.

Every product optimization is to solve product problems; every product upgrade is to let dealers serve more customers. Just like the constant replacement of Apple's mobile phones, Ruiqite products have always used the best products to serve every partner.